Cyanate Ester Resin Market Size and Forecast, By Derivative (Bisphenol-based, Novolac-based), By Application (Aerospace, Automotive, Electronics, Industrial), And Trend Analysis, 2015 - 2025

- Published: September, 2018

- Format: Electronic (PDF)

- Number of pages: 71

- Industry: Advanced Materials

Industry Insights

The global cyanate ester resin market was valued at USD 225.85 million in the year 2017 and is projected to expand at a CAGR of over 11% during the forecast period. Unique properties, such as high thermal efficiency, low moisture uptake and low dielectric constant are fueling the demand for cyanate ester in automotive, electronics, aerospace, defense, energy components, and wireless communication sectors.

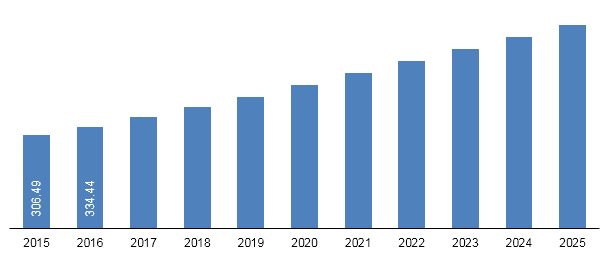

Global cyanate ester resin market, by bisphenol-based derivative, 2015 - 2025 (Tons)

Increasing application of lightweight materials in an effort to reduce carbon footprint has resulted in rising demand for these materials. Strict fuel economy standards have been implemented to control carbon footprint of the automobile industry.

The Corporate Average Fuel Economy (CAFE) standards set by U.S. have made automobile market competitive, in terms of usage of lightweight materials in the body and frame applications. With the growing production of aircrafts, demand for cyanate ester is also expected to increase. However, large-scale adoption of the product is restricted due to high costs.

Segmentation by Derivatives

• Bisphenol-based

• Novolac-based

Bisphenol-based derivatives led the global cyanate ester resins market accounting for over 1.5 kilo tons of the overall volume in 2015. Bisphenol derivatives segment is also expected to be the fastest-growing segment with volume growth exceeding a CAGR of 8% during the forecast period. This growth can be attributed to the enhanced properties offered by the presence of bisphenol. Cyanate ester resins derived from bisphenol are tougher as compared to epoxy resins. Furthermore, curing process of this type is easier than epoxy resins. Bisphenol A, Bisphenol E, Bisphenol F, Bisphenol M dicyanate (BMCy), and Dicyclopentadienyl bisphenol cyanate (DCPCy) are the commercially used bisphenol derivatives.

Novolac-based cyanate esters are known as commercial resins due to their thermal performance. They provide essential flame retardancy and low emission of smoke. They are extensively used in cabins of the latest Airbus and Boeing airplanes. Huntsman sells novolac-based cyanate esters, under the brand name AroCy XU 371, suitable for high-temperature adhesives and composites. They can withstand a glass transition temperature of up to 300°C.

Segmentation by Application

• Aerospace

• Automotive

• Electronics

• Industrial

• Others

In terms of application, aerospace led the global cyanate ester resin market accounting for a revenue share of over 55.0% in 2017. It is projected to expand further at a CAGR of 11% during the forecast period. Cyanate ester resin is used in various parts of aircrafts, such as cooling unit, rotor assembly, pressure lines, pressure vessels, engine housings and flywheels. Furthermore, growth opportunities in emerging market and aging of traditionally built aircrafts are generating demand for advanced, lighter, and stronger chemical technologies in aerospace industry.

Unique properties of these resins have compelled manufacturers to conduct extensive R&D to broaden the application scope in fields apart from aerospace. In the automotive industry, brakes and exhaust of racing cars are made of cyanate ester resin. These composites can withstand the high temperature ranges within the exhaust and are fire-resistant. Various other applications include engine covers, heat shields, brake ducts, and crash structure.

Electronic applications of cyanate esters are growing due to their low dielectric constant. Communication housing, radar microwave transparency, and computer circuitry are expected to increase application scope in the electronics industry. High-speed Printed Circuit Boards (PCBs) is another major application. Nearly 70% of the already manufactured high-speed PCBs across the globe are based on cyanate ester resin.

Segmentation by Region

• North America

• U.S.

• Canada

• Europe

• Germany

• Asia Pacific

• China

• India

• Central & South America

• Middle East & Africa

North America is the largest, as well as the fastest-growing, region for cyanate ester resin market. It was valued at USD 81.83 million in 2017. Top customers, such as Airbus and Boeing, are located in North America, which is expected to drive demand in the forthcoming years. Demand from the aerospace industry in North America is expected to grow over the next few years.

Competitive Landscape

The market is consolidated in nature and has a few companies manufacturing cyanate ester resin based on bisphenol and novolac derivatives. Hazardous nature of preliminary raw materials, such as cyanogen chloride and cyanogen bromide to obtain monomeric compound and the need for corresponding technology may pose challenge for new market entrants. Some of the prominent companies in the global cyanate ester resin market include Lonza Group; TenCate; Cytec Industries Inc.; Mitsubishi Gas Chemical Company, Inc.; Huntsman Corp.; Hexcel Corp.; and Novoset LLC.

Choose License Type

- World's largest premium report database

- Transparent pre & post sale customer engagement model

- Unparalleled flexibility in terms of rendering services

- Safe & secure web experience

- 24*5 Research support service