Pneumatic Conveying Systems Market Size and Forecast, By Operating Principle (Dilute Phase, Dense Phase), By Technology (Vacuum, Positive Pressure, Combination), By End-Use (Food, Pharmaceutical, Rubber & Plastic, Ceramics) And Trend Analysis, 2014 To 2025

- Published: August, 2017

- Format: Electronic (PDF)

- Number of pages: 92

- Industry: HVAC & Construction

Industry Insights

The global pneumatic conveying systems market size was estimated to be worth USD 22.11 billion in 2016 and is likely to be driven by the rising demand for robust and advanced material handling equipment. Rising awareness regarding the prohibition of contamination, advancement of technology and increasing demand for these machines in various sectors such as food processing, pharma and ceramic manufacturing.

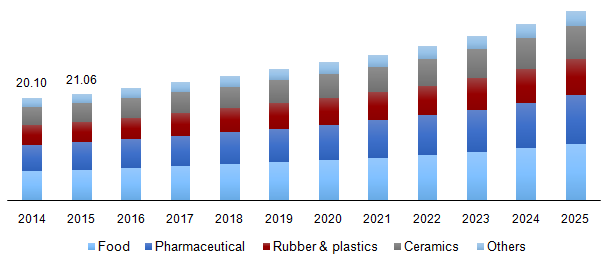

Global pnuematic conveying systems market, by end-use, 2014 - 2025 (USD Billion)

The global market for pneumatic conveying systems is expected to gain momentum owing to the expansion of manufacturing industries such as in food & pharmaceutical industry and usage of automation to produce efficiently & effectively. Integration of mechanization in pneumatic conveyors and innovation in product feeding & receiving technologies are expected to drive the growth of pneumatic conveying systems industry over the forecast period.

The growth of the industry is expected to be driven by stringent government regulations regarding health and safety of employees in developing countries. As manual material handling has been the main cause of injuries especially in chemical and pharmaceutical industries, it has been made mandatory to use pneumatic conveyors for maintaining safety at the workplace.

The growth and expansion of the manufacturing sector in emerging economies such as India and China are projected to drive the sales for pneumatic conveying systems in Asia Pacific region over the forecast period. However, the high cost of investment required for installing a pneumatic conveying equipment is expected to have an adverse impact on the growth of the market over the projected period.

Segmentation By Operating Principle

• Dilute phase

• Dense phase

Dilute phase conveying systems operate with high speed and often used with nonabrasive and nonfragile materials, commonly used for powders and granules. In 2016, the segment contributed to 73% of the global market share and is expected to grow on account of its ability for handling a broad range of materials including sugar, plastic granules, flour, sodium bicarbonate, hydrated lime, and zinc oxide.

Dense phase pneumatic conveying equipment market was estimated to be worth USD 5.96 billion in 2016. It operates with low speed resulting in less wear and tears for both materials being transmitted as well as the system.

The equipment is ideal for fragile material, and mixtures as low velocity prevent the material from breaking down. It is also suitable for slightly hygroscopic material and abrasive or friable material as slow speed reduces abrasion of conveying lines. Dense phase conveying is popular for transfer of material such as sand, fly ash, and carbon black.

Segmentation By Technology

• Vacuum system

• Positive pressure system

• Combination system

Positive pressure equipment emerged as the dominant service segment in 2016 and accounted for 49.8% of the overall revenue market share. The use of the constant mass air flow with positive pressure in this equipment prevents plugging, which minimizes abrasion resulting in less power consumption thereby lowering the cost of maintenance. This is one of the trends which is expected to result in pressure equipment witnessing the fastest growth over the forecast period.

Vacuum pneumatic conveying systems market was valued at USD 6.77 billion in 2016. These machines are suitable to send materials at low to moderate capacities over medium distances. This segment is expected to gain fame in next few years due to its incremental utilization to transfer material from diverse sources including storage vessels, trucks & railcars, process equipment, to an individual or several destinations.

Segmentation By End-Use

• Food

• Pharmaceutical

• Rubber & Plastics

• Ceramics

• Others

Food was the dominant end use segment in the global market accounting for 28.7% in 2016. Abundant benefits such as increased reliability, reduced risk of material spillage, lower energy, increased productivity, reduced system footprint, lower operational costs, lower maintenance costs and flexibility to extend applications are the key factors to drive the demand over the forecast period and this trend is expected to continue over the forecast period.

Pharmaceutical was valued at USD 5.68 billion in 2016 and is anticipated to experience high growth over the projected period. An increasing quality and performance in hospitals to place orders for the installation of complex pneumatic tube machine developed according to latest technical standards to meet the highest demands is expected to drive growth.

Segmentation By Region

• North America

• U.S.

• Canada

• Europe

• Germany

• UK

• Asia Pacific

• China

• India

• Japan

• Central & South America

• MEA

Asia Pacific market was worth USD 4.74 billion in 2016 and is anticipated to witness significant growth over the forecast period due to the rising awareness regarding optimization of material handling operations and installation of more economical conveying equipment. Rapid industrialization in countries India, Japan and China coupled with government regulations regarding safety of employees in manufacturing industries is expected to result in rising demand for pneumatic conveying systems.

Europe accounted for the highest revenue share at 30.2% in 2016. Rising demand from food industry coupled with the increasing number of food packaging and plastic industries, especially in Germany and UK, is expected to result in increasing demand for pneumatic conveying systems. Additionally, the presence of several regulatory bodies across the region providing favorable mandates may also contribute the regional growth of the market.

Competitive Landscape

The global market is consolidated owing to the presence of a limited number of manufacturers. Key vendors include Hillenbrand Inc, Schenck Process Holding GmbH, DongYang P&F, Cyclonaire Corporation, and KC Green Holdings.

Companies are focusing on research for the development of innovative products to increase their presence globally. For instance, in January 2017, Zeppelin Group invested in new laser cutting machine for its Rödermark site.

Choose License Type

- World's largest premium report database

- Transparent pre & post sale customer engagement model

- Unparalleled flexibility in terms of rendering services

- Safe & secure web experience

- 24*5 Research support service